The new BS 2 keeps the main technical features of the BS 15 unchanged but adds important improvements that make it better. This range has been developped for applying and spraying of protective and soundproofing materials like gravel protection, anti-rust, vibration-damping, bituminous paints, bituminous and protective waxes both solvent -based and water-based of last generation.

Application : Application and spray of protective and soundproofing materials water-based materials.

Body : Die-cast aluminium body with a new design integrated tank support. Tank : In aluminum welded with protective treatment with high hardness and strength. Cover : Realised in aluminum with integrated coupling, which has been threaded to allow the screw of the suitable cans, with high hardness and strength to the corrosion. Needle : Stainless steel. Nozzle and Cap : Chuck brass prolonged nozzle and cap. Air consumpt. : Approximate 200-300 l / min Noise level : <80 dBA Net weight : 1.937 g.

Working pressure : 2-4 bar / Maximum pressure allowed 8 bar.

Connection: 1/4 male gas

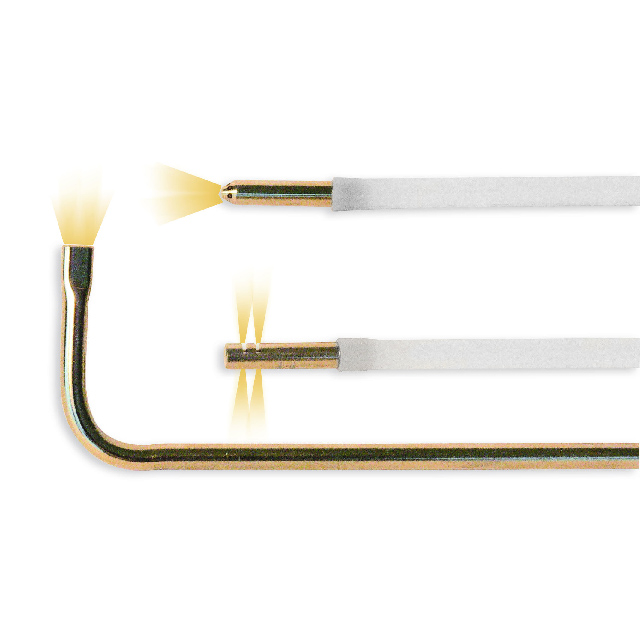

Options : with a quick-coupling single tube extension 1500 mm long and three interchangeable spraying heads: a 90° nozzle, a straight nozzle 360° spray and an anterior straight nozzle rose-pattern spray.

Single package: in neutral carton box

- Thanks to the multi-possibilities to adjust both the air’s flow and the material’s quantity and pulverisation, the guns allows the user to obtain a wide range of orange peel surface of different features. In this way the user has the possibility to recreate the surface as it was at the beginning.

- The tank’s capacity , which is under pressure, allows the gun to work both with loose products and using the standard cans on sale in commerce of 1 kg. It can be directly screwed on the cover’s threaded coupling.

- The underpressure tank guarantees that during the work’s breaks the material can be left inside the tank and it will not undergo any deterioration. The under pressure tank allows to this gun to work at very low pressure ( 2 – 3 bars) which avoid the formation of the spraying fog; furthermore it can be used besides standard products also with products that have high solid contant so thereforewith a little percentage of solvent inside that allows in this way to not pollute the work’s environment.